profiRounder impression

Heesemann machines for sheet metal finishing

profiRounder is the first freely configurable deburring system for the dry processing of sheet metal parts. It was designed for the dry mixed processing of steel, stainless steel, aluminum and copper.

profiRounder deburring systems– full flexibility through a wide variety of processing units and tools

profiRounder Finishing System

profiRounder is the first freely configurable system for the dry processing of metals. It was designed for the dry mixed processing of steel, stainless steel, aluminum and copper.

Slag Removal

With the profiRounder, we offer a machine solution that enables optimal slag removal. The system stands out for its high flexibility, which proves especially beneficial in slag processing applications.

Depending on your company’s specific needs, the profiRounder can be adapted accordingly—always tailored to your requirements. It pays off with reliable results that lead to greater customer satisfaction.

Slag processing can also be integrated using a RUT unit equipped with cup brushes featuring hardened steel pins, ensuring optimal processing of your workpieces.

.jpg)

Deburring

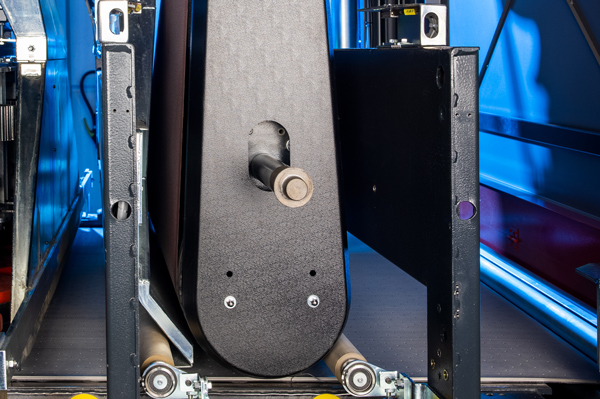

The profiRounder deburring systems remove the main burr using a wide belt unit. Depending on the material and the nature of the burrs, grinding belts such as K24/K36 for flame-cut parts or K60/K80 for laser-cut parts are used.

Properly dimensioned and powerful units are key to successful deburring. For example, profiRounder systems utilize Ø 250 mm and Ø 300 mm contact rollers, combined with drive systems of up to 22 kW.

To remove the main burr, the contact roller unit is set slightly below the surface of the part. As the workpiece passes under the contact roller, the rubber coating compresses slightly, concentrating the grinding action on the edges—where the burrs are located.

Oxide Removal

The disc brush with wire bristles is the most common tool for removing oxide. It uses cord wire, which is capable of withstanding alternating bending loads. The brush height is set to slightly more than 50% of the workpiece thickness, ensuring complete oxide removal in just two passes.

At Heesemann, this tool is implemented in the RUT unit. The unit’s KinematIQ system ensures that all edges are processed with consistent intensity. This guarantees there are no "shadow areas" where oxide might remain—an issue often unavoidable with cross-brushing and planetary units due to the limitations of their process design.

Edge Rounding

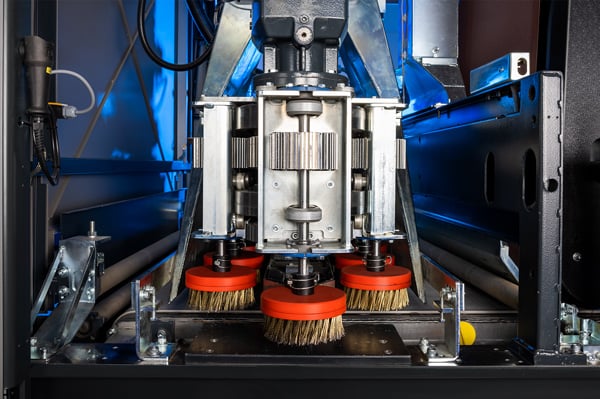

The profiRounder offers innovative edge-rounding systems with diverse grinding processes. For intensive edge rounding, two options are available: RUL units with lamella grinding rollers and RUT units with grinding discs. Both ensure 100% uniform edge processing.

The RUL unit features six brushes that rotate on both horizontal and vertical axes. These orbit around the conveyor belt, guaranteeing even treatment of all workpiece edges. The lamella rollers, with a 350 mm diameter and 365 mm width, can achieve large radii up to 2 mm and are safe for galvanized or foiled sheets—preserving zinc layers and foil coatings.

They are also ideal for parts with threaded holes, embossing, or small bends. A unique pressure roller design—placed before, between, and after the brushes—securely holds even long and narrow parts in place without the need for a vacuum.

Surface Finishing

To produce a surface finish during the pass, a suitably fine abrasive is used on the contact roller. This makes it an ideal solution for creating decorative ground surfaces.

Under optimal conditions, finish grinding operates at significantly higher feed rates than deburring. While the feed rate for deburring typically ranges from 0.5 to 3 m/min, surface grinding is performed at 8 m/min or more.

Consequently, optimum results are achieved by running the sheets requiring finishing—often just a small percentage of total production—through the machine a second time.

If finishing is required during the same pass, an additional wide belt unit with a contact roller is integrated into the machine as the final or second-to-last unit.

The Heesemann brand

Renowned as the world market leader in sanding machines, we also offer state-of-the-art deburring systems. After an in-depth analysis of the specific market requirements—particularly regarding workpiece edge rounding—we have developed units featuring cutting-edge technology. These are equally suitable for applications using either abrasive lamella or abrasive discs, both of which demonstrate their full benefits.

This enables panels to be processed with absolute uniformity and high intensity. The system delivers impressive efficiency and high throughput.