BeltMaster K4TD-1350

For finishing as well as 360° deburring, edge rounding, oxide removal or orbital finishing. Features three units in a working width of 1350 mm.

BeltMaster K4TD-1350

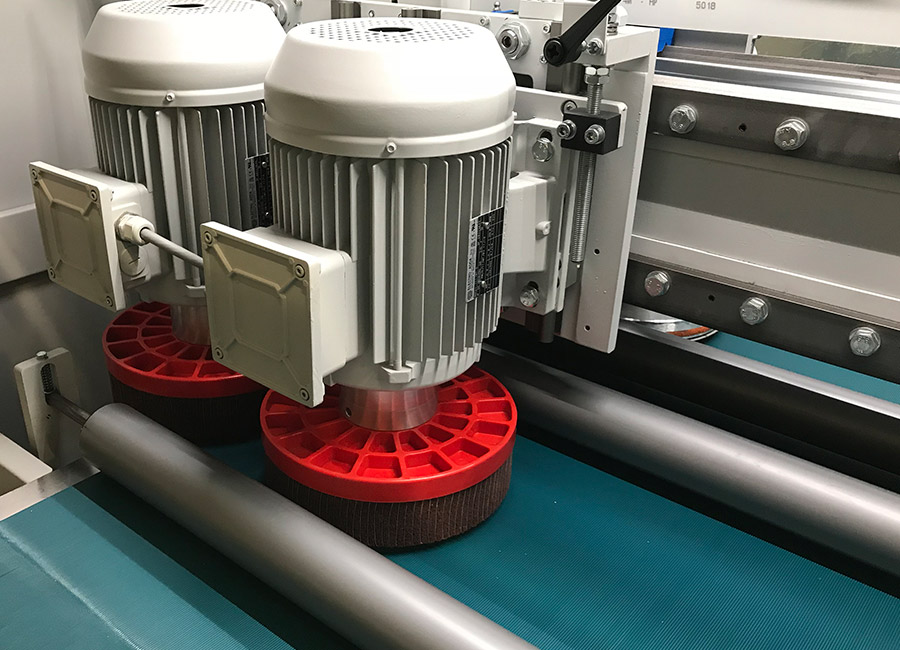

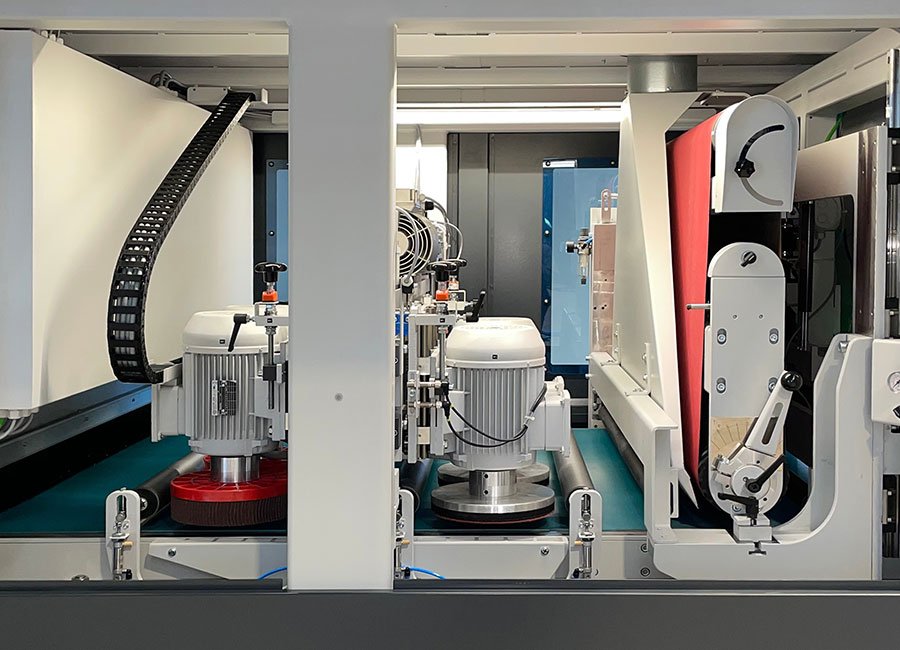

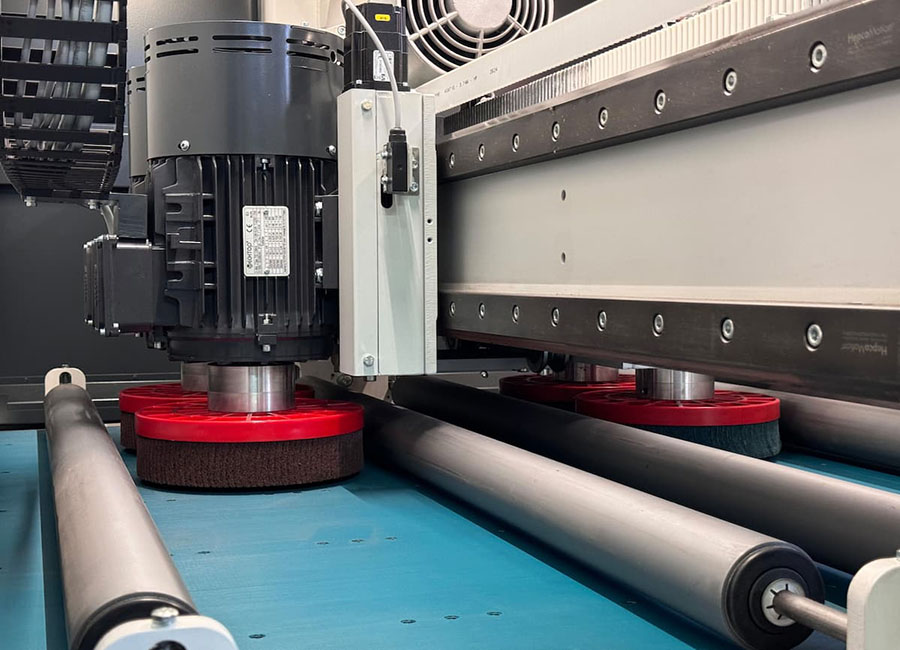

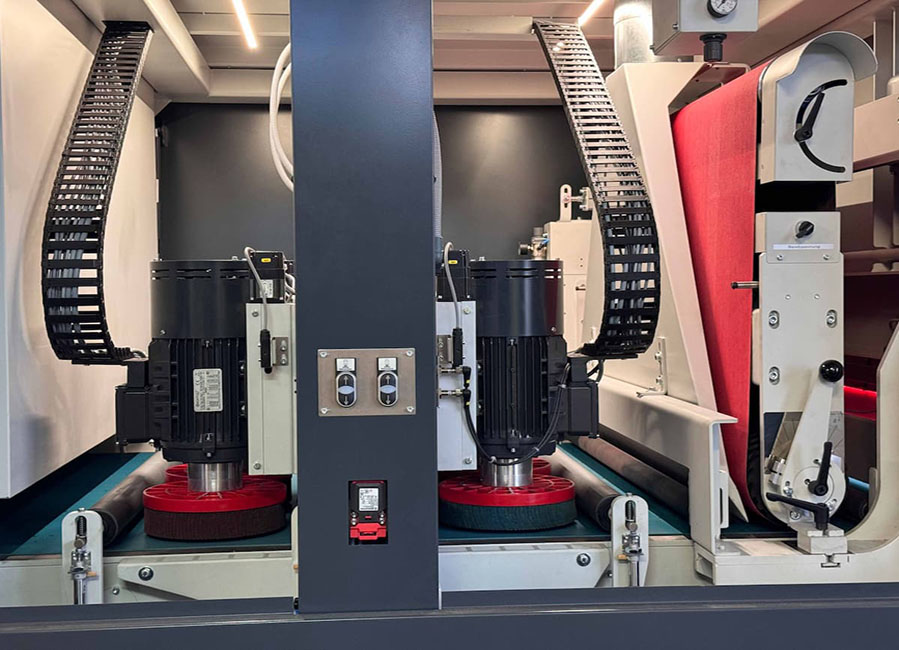

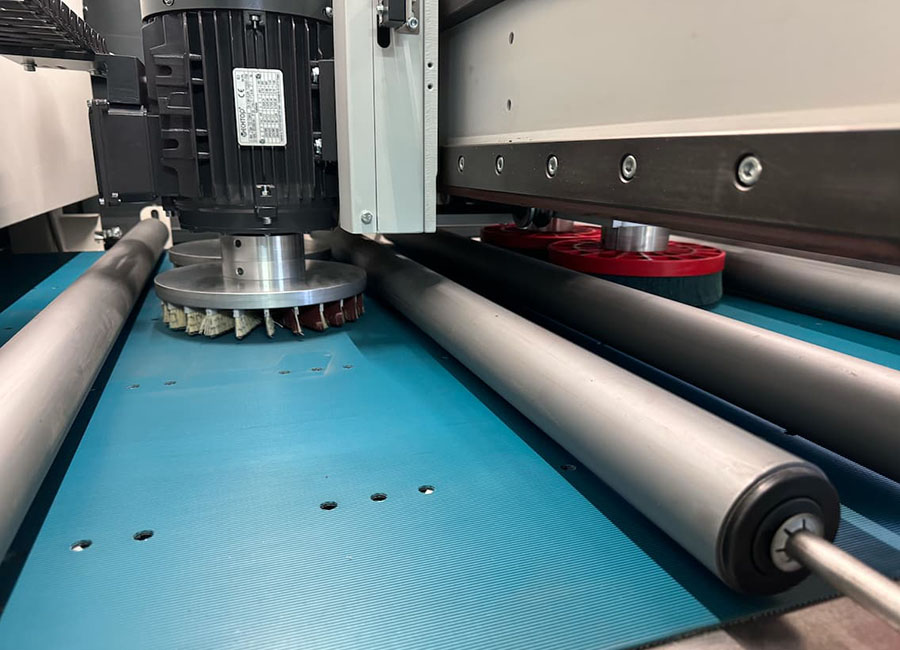

The BeltMaster K4TD is equipped with one abrasive belt unit followed by two oscillating disc units, each with two large rotating discs, making it ideal for grinding, deburring, edge rounding and oxide removal.

Genral

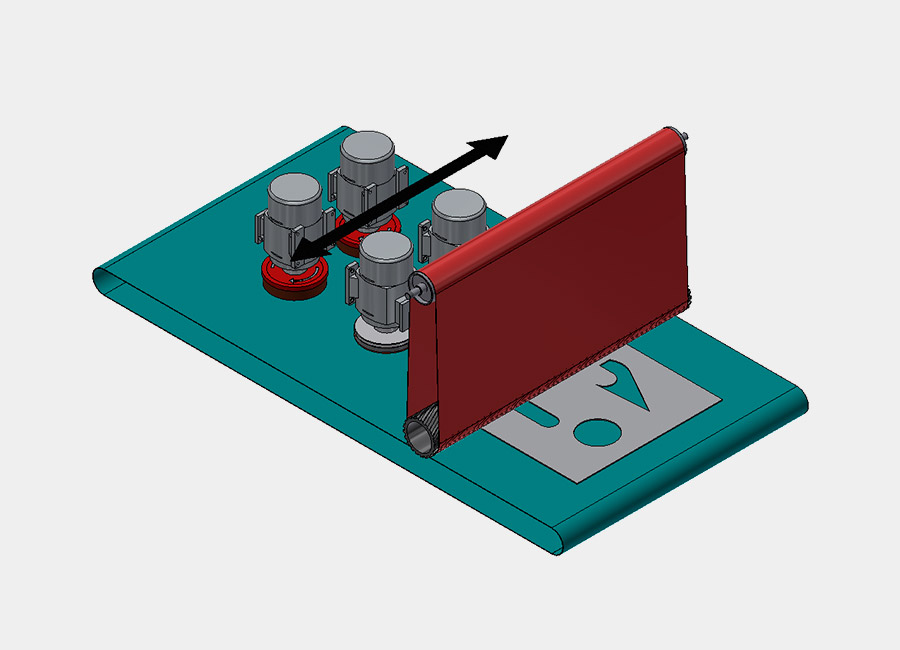

The BeltMaster K4TD is equipped with abrasive belt unit and the 4TD unit with four large rotating discs that oscillate across the entire width of the conveyor belt. The abrasive belt is equipped with our unique tolerance sanding device. The combination of the wide belt unit and our 4TD disc concept makes this system a versatile solution for sanding, deburring, rounding, oxide layer removal or orbital finishing with one machine.

- Abrasive belt unit for sanding or deburring with infinitely variable belt speed

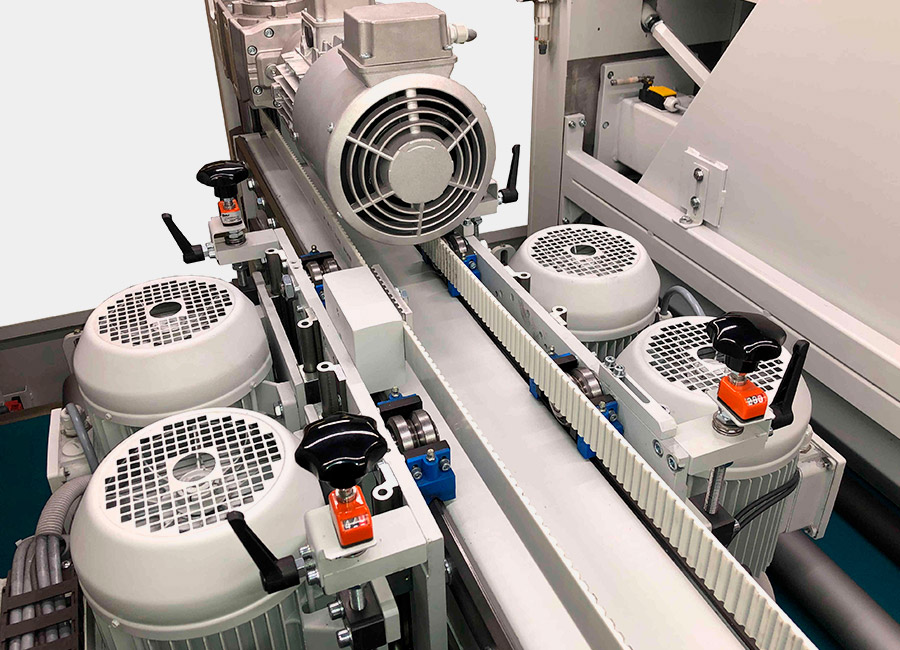

- Two disc units on the infeed side, two disc units on the outfeed side

- Oscillation across the entire belt width

- All inside and outside edges are processed from all angles and directions

- Uniform tool wear of the discs regardless of the placement of the workpiece on the conveyor belt

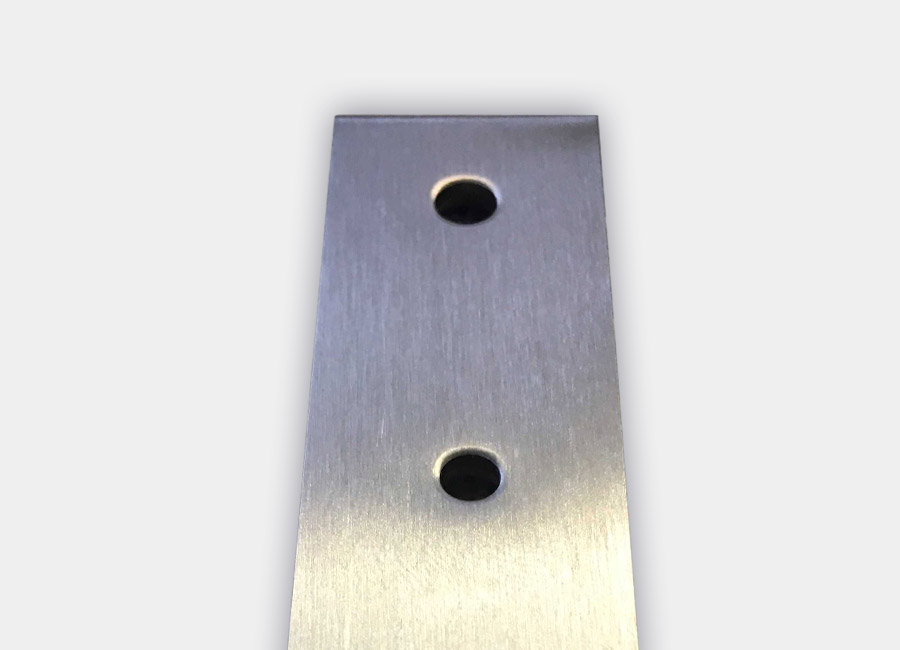

- Quick and easy tool change for material mixes

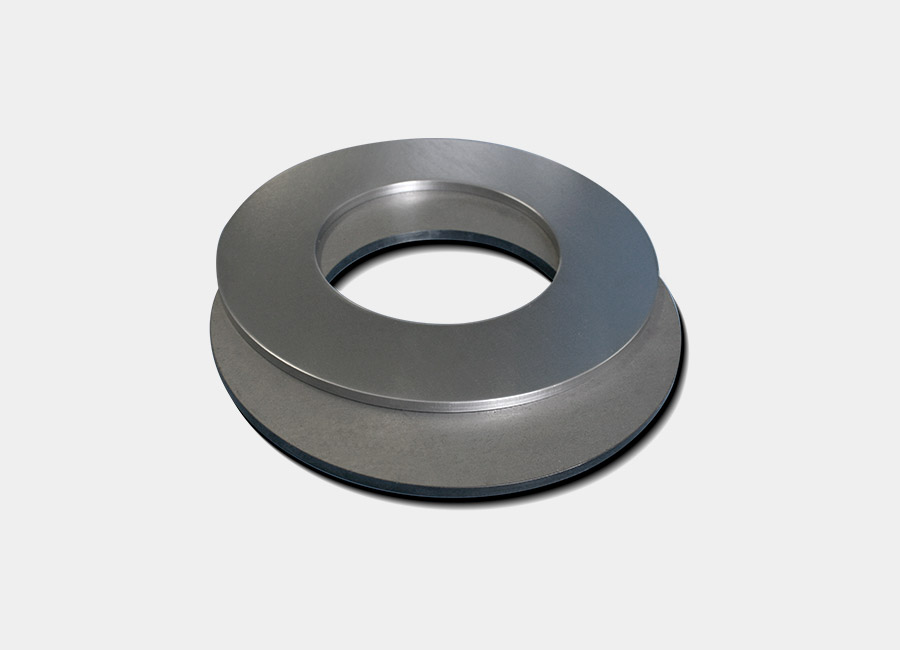

- Versatile application options thanks to the wide variety of tools available

Possibilities

- Straight line graining and finishing

- Deburring – rounding + stronger rounding in one operation

- Deburring – rounding – oxide layer removal

- Deburring – rounding – orbital finish

- Processing of punched parts or water jet-, laser- or plasma-cut sheet metal

- Deburring and rounding of 3D stamped parts

- Processing of small parts from 20 mm diameter

- Processing of foil-coated or galvanised sheet metal

- Processing of steel, stainless steel, aluminium…

- max. working width: 1350 mm / 1500 mm

- Shortest workpiece length 20 mm

- Work piece thickness: 0.3 mm – 80 mm

- Rotating Cleaning Brush - Ideal for cleaning the conveyor belt from below on the outfeed side.

- Infinitely Variable Disc Rpm - When using different disc tools for different applications it is necessary to adjust the the disc rpm.

- Quick-Fix Tool Connector - Quick-Fix tool connector for speedier changing of discs e.g. when alternating between steel and stainless steel.

- Lighting - LED lights inside the machine.

- Magnetic Track - Permanant magnetic track below the feed belt for holdin down smaller steel parts. This is recommended when using OxideDiscs or HammerDiscs.

- Dust Extraction Unit - Loewer offers a range of dust extraction units for removing harmful abrasive dust. Depending on the application at hand they are available for wet or dry processing.

- Aluminium Extraction Kit - When processing aluminium a lot of fine, light dust is created. Extraction hoods around the discs enhance the dust extraction process.

- Floating head system - The unique LOEWER floating head system is designed for the abrasive belt unit and makes it possible to regulate the grinding pressure. It allows the entire unit to move out of the way if the grinding pressure gets too high. The system prevents the workpiece overheating and protects the expensive contact drum from damage.

- Conveyor tables - When processing longer work pieces it is helpful to use conveyor tables. These are available in different lengths and widths. As an optional extra the feed speed can be linked up to the feed speed of the machine.

- Vacuum - High-pressure vacuum fan with frequency converter and perforated conveyor belt / table for holding down the workpieces.

- Automatic calibration - Motorised adjustment of the individual discs with automatic calibration after tool change or for wear compensation.

Gallery