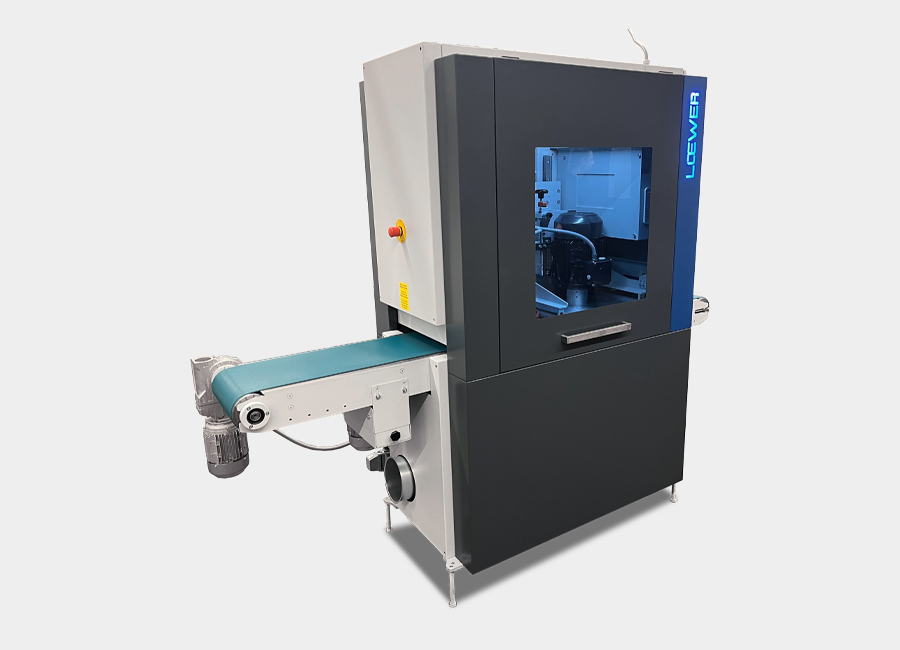

CrossMaster DD 300

For deburring and edge rounding of small parts in working widths of 200 mm or 300 mm.

CrossMaster DD 300

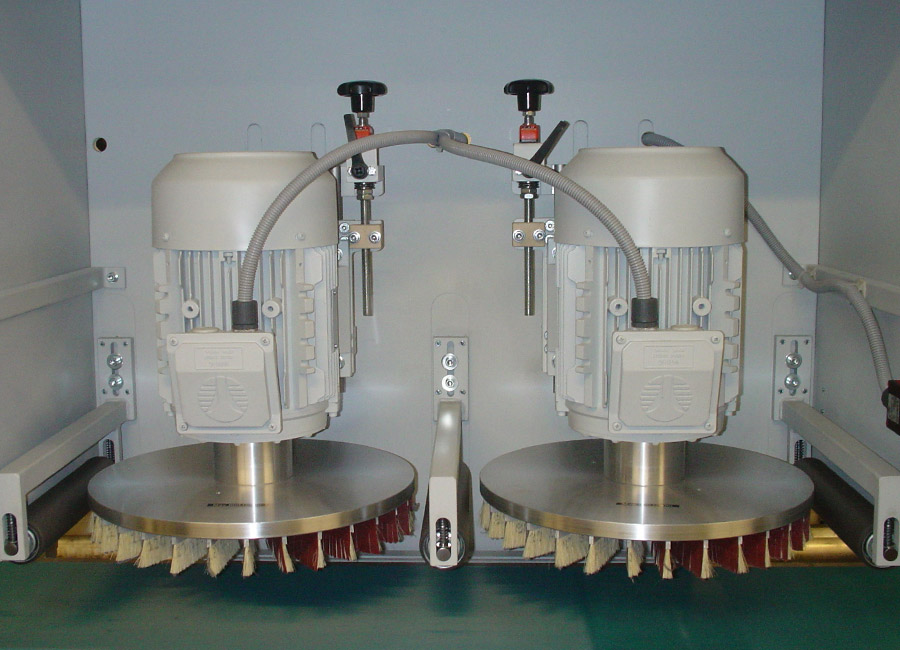

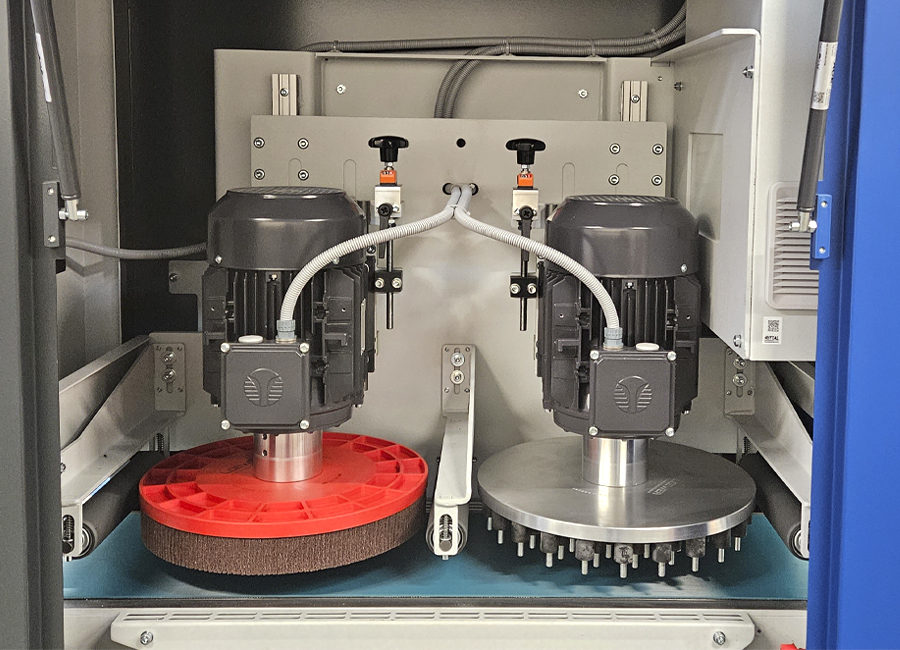

The CrossMaster DD is equipped with two disc tools on the top. Depending on the application it can be used with deburring and/or edge rounding discs. The disc tools push the workpiece against the feed belt during operation so it is possible to process even very small workpieces starting from 20 x 20mm. The Crossmaster DD is available in 150 or 300mm working width.

General

The CrossMaster DD is equipped with two disc units, one for deburring and one for edge rounding. The workpieces are placed on a high-friction feed belt. The disc tools, which are parallel to the workpiece, push the workpiece against the feed belt during operation. As a result, it is possible – on a disc-only machine – to process even very small workpieces starting from 20 x 20 mm.

There are two models to choose from:

CrossMaster DD 300S: Heavy-duty model with 300 mm working width with a wide range of options.

CrossMaster DD 200 Mini: Compact model with 200 mm working width, well equipped as standard, without further options, but at a very good price.

- Two rotating discs in a row

- Disc diameter larger than conveyor belt width, processing from two directions

- Uniform tool wear regardless of the position of the workpiece on the conveyor belt

- Simple and quick tool change for material mix, as only 2 tools need to be changed

- Versatile application options due to the large variety of available tools

- Low investment, tool and operating costs

The CrossMaster DD 300S is the heavier version, with a working width of 300 mm. Depending on requirements, the machine can be equipped and customised with various options.

The CrossMaster DD 200 Mini is a compact machine with a working width of 200 mm. Due to its compact size, it can easily be used without a workpiece return conveyor. The machine is well equipped as standard, with motorized thickness adjustment, digital display, inverters and a feed belt cleaning brush. Use the CrossMaster DD 200 Mini as an additional machine for processing small parts faster, with less energy and without the risk of damaging a larger machine with small parts.

Possibilities

- Deburring and edge rounding of laser cut, plasma cut, water cut and punched parts in one pass

- Deburring and edge rounding of 3D punched parts

- Processing of small parts starting from 20 mm x 20 mm

- Processing of foil covered or zinc plated parts

- Processing of steel, stainless steel and aluminium

- Max. working width: 200 mm or 300 mm

- Shortest workpiece length: 20 mm

- Sheet thickness: 0.3 mm – 80 mm

- Vacuum Device - For holding down smaller and lighter workpieces. For most applications the vacuum device is often not required but it can be ordered at a later stage should it become necessary.

- Quick-Fix Tool Connector - Quick-Fix tool connector for speedier changing of discs e.g. when alternating between steel and stainless steel.

- Dust Extraction Unit - Loewer offers a range of dust extraction units for removing harmful abrasive dust. Depending on the application they are available for wet or dry processing.

- Pneumatic Weight compensation - Weight of the arm and grinding pressure pneumatically adjustable for more comfort.

Gallery