SmartGrinder

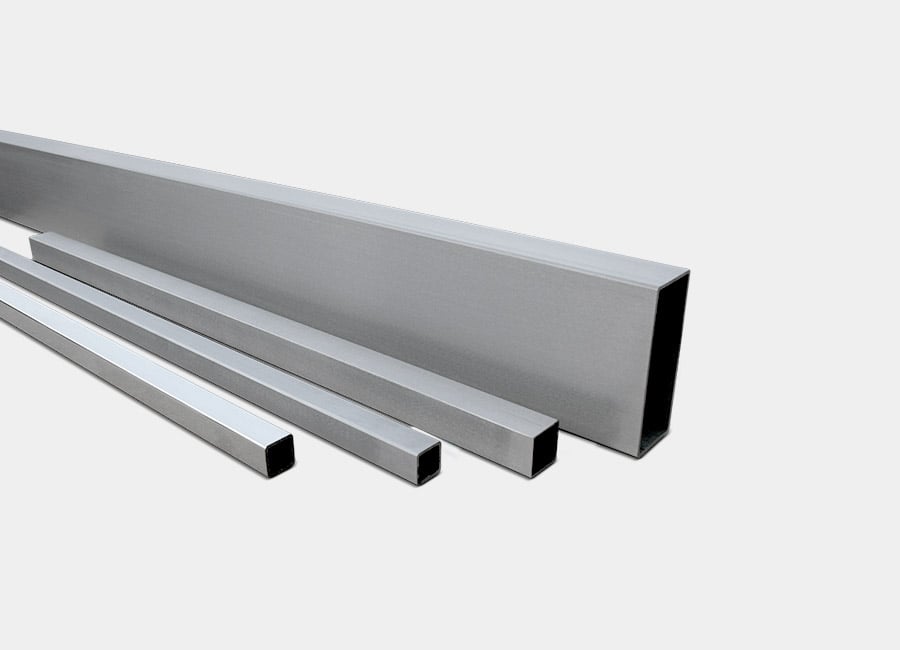

For abrasive belt grinding and finishing of rectangular tubes and flat bars in working widths of 150 mm and 300 mm.

SmartGrinder SG 150 K

The SmartGrinder SG 150 K - the ideal grinding machine for medium-sized production.

Great value for money made possible by manufacturing a large number of machines with standard features.

Highly versatile grinding, bur removing or finishing of flat bar, sheet metal or hollow sections. The wet grinding facility makes it ideal for a mixed production of steel, stainless steel or aluminium.

- Working widths: 150 mm and 300 mm

- Material thickness: 0,5 mm – 150 mm

Options

- One to four stations in a line

- For wet or dry processing

- Floating head system i.e. with adjustable grinding pressure allowing the abrasive belt unit to move out of the way if grinding pressure gets too high

- Permanant magnet below the feed belt for holding down smaller steel parts

- Demagnetization below the feed belt on outfeed side

- Infinitely variable rpm of abrasive belt

- Additional hold-down rollers

- Feed belt with 90° stoppers for shorter stainless steel or aluminium parts

- Paper belt filter

- Range of dust extraction units available

General

The SmartGrinder SG models are sturdy, easy-to-use abrasive belt grinding machines „Made in Germany“. The modular concept with one to four stations in a line together with a range of optional extras make the machine very versatile and adaptable to different grinding tasks. The SmartGrinder SG is especially suitable for graining or finish grinding of flat bars and hollow sections.

- Working widths of 150 mm and 300 mm

- One to four stations in a line

- Abrasive belt or drum units

- For wet or dry processing

Possibilities

- For abrasive belt grinding of rectangular tubes, decorative straight-line finishing on stainless steel or preparation for chrome plating

- For abrasive belt grinding of flat bars

- Deburring

- Finishing

- Roughening

- Processing of steel, stainless steel and aluminium

Gallery