DiscMaster 4TD-1000

For 360° deburring, edge rounding, oxide removal or orbital finishing. Features two units in working widths of 1000 mm, 1500 mm or 2000 mm.

DiscMaster 4TD-1000

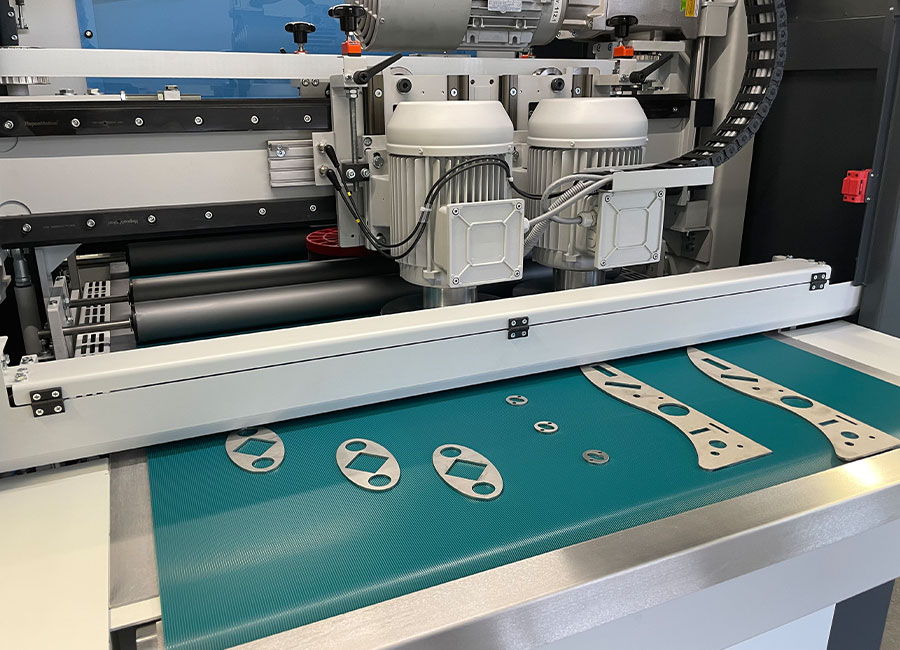

The DiscMaster machines offer the answer to the question of finishing the difficult parts. Bur removal from small or large parts has been a challange for many machines for some time. The DiscMaster allows the processing of both in the same machine. Built 100% in Germany and of a robust design insure it can be effective even in a difficult enviroment.

Genral

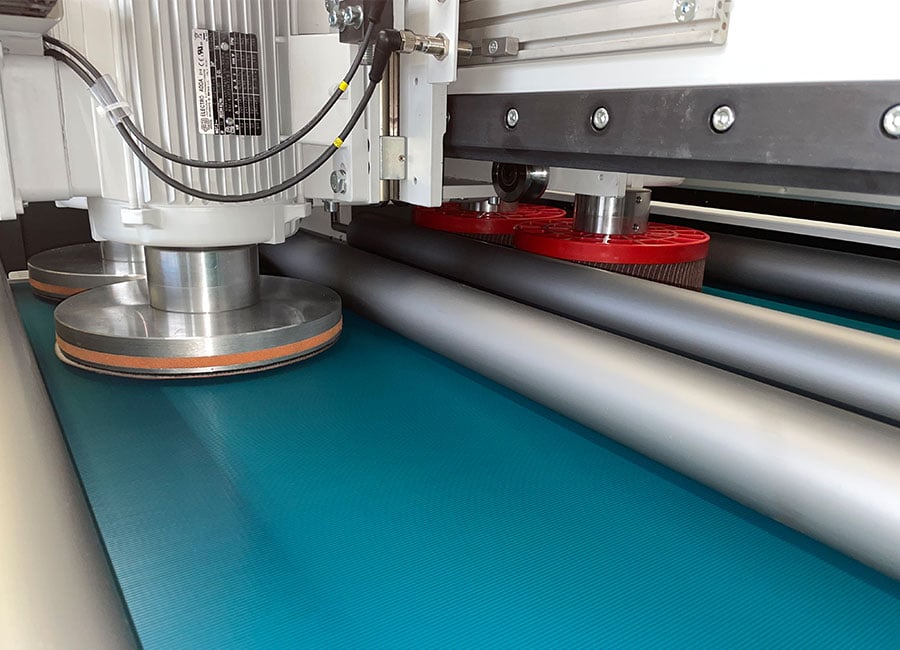

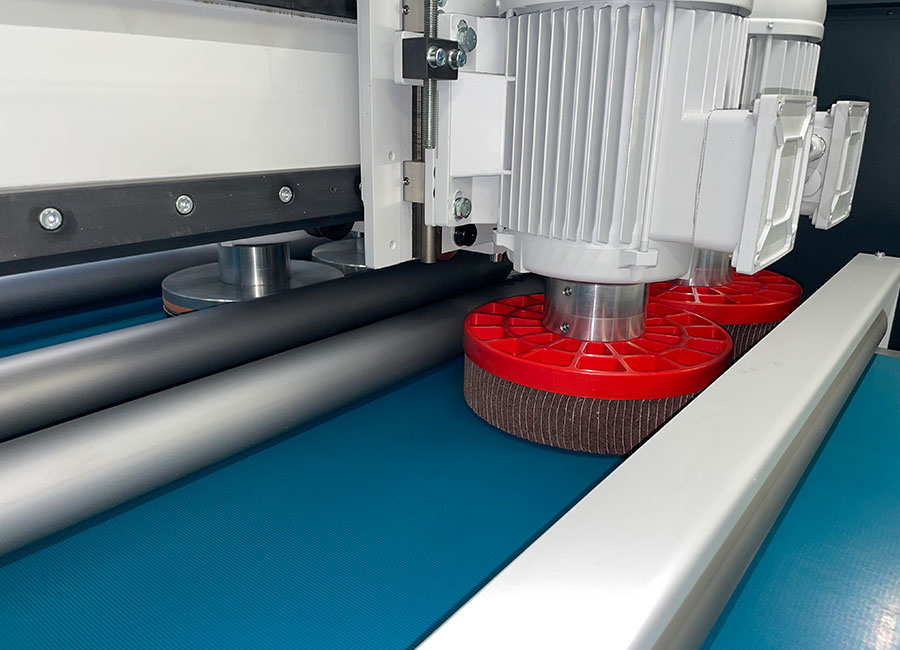

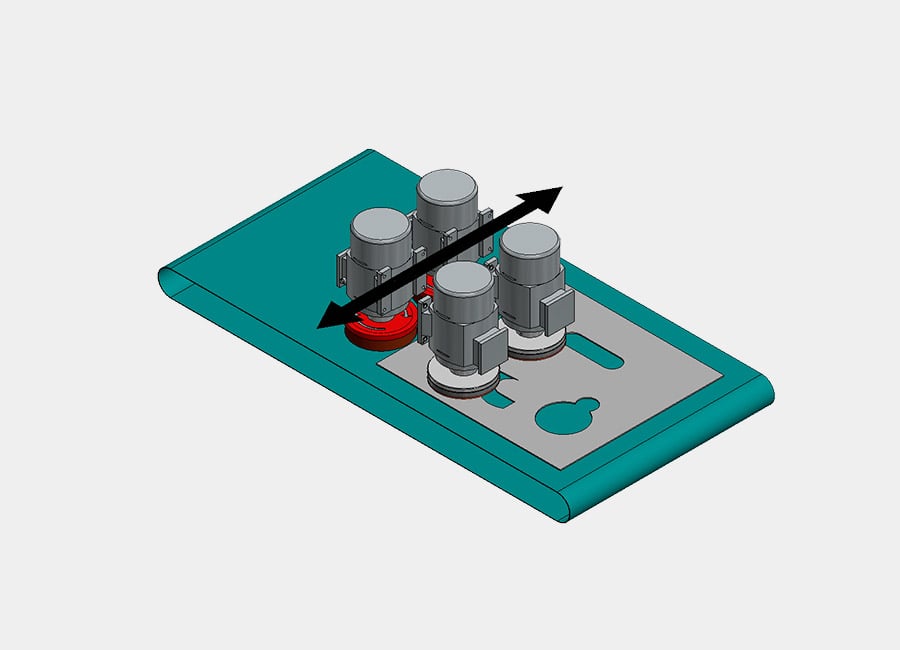

The DiscMaster 4TD is equipped with two deburring discs and two edge rounding discs. The discs oscillate continuously over the workpiece during throughfeed. The interaction of the rotation with the large oscillation stroke leads to high quality deburring and edge rounding results. The large variety of disc tools available makes the machine very versatile.

- Two large discs both at infeed side and outfeed side

- Large oscillation stroke over full width of the feed belt

- All inside and outside edges are processed from all angles and directions

- Even wearing of abrasive tools irrespective of the size of the workpiece or where it is placed on the conveyor belt.

- Quick change of tools when switching between materials – only four discs need to be changed

- Large variety of disc tools available makes the machine very versatile

Possibilities

- For deburring and edge rounding laser-cut, plasma-cut and water-cut parts

- For deburring and edge rounding 3D punched parts

- For edge rounding and orbital finishing in one pass

- Processing of small parts from 20 mm x 20 mm

- Processing of foil-covered or zinc-plated parts

- Processing of steel, stainless steel and aluminium

- Working widths: 1000 mm, 1500 mm and 2000 mm

- Smallest part size: 20 mm x 20 mm

- Material thickness: 0,3 mm – 70 mm (100 mm)

- Rotating Cleaning Brush - For cleaning the conveyor belt from below on the outfeed side.

- Infinitely Variable Disc Rpm - When using different disc tools for different applications it is necessary to adjust the the disc rpm.

- Quick-fix Tool Connector - Quick-Fix tool connector for speedier changing of discs i.e. when switching between steel and stainless steel.

- Lighting - LED lights inside the machine.

- Magnetic Track - Permanant magnetic track below the feed belt for holding down smaller steel parts. This is recommended when using OxideDiscs or HammerDiscs.

- Dust Extraction Unit - Loewer offers a range of dust extraction units for removing harmful abrasive dust. Depending on the application at hand they are available for wet or dry processing.

- Aluminium Extraction Kit - Whe processing aluminium, a large amount of fine, light dust is created. Extraction hoods around the discs greatly enhance the dust extraction process.

- TouchPanel Control - Coloured touch panel for setting and displaying machine parameters as well as for storing machine settings.

- Conveyor Tables - When processing longer work pieces it is helpful to use conveyor tables. Löwer offers a wide range of tables in different lengths and widths. As an optional extra it is possible to link the variable feed speed to that of the machine.

Gallery