Autopulit Polishing Machines

Automation

Since 1961, Autopulit has been pioneering the manufacturing industry of special automated equipment for abrasive belt grinding, finishing, bright finishing, deburring and micro-finishing of metallic parts.

Their continuous improvement in R&D has brought the company into the 21st century. Incorporating the latest technologies, CNC equipment and robotics, Autopulit is leading the industry in specialty finishing equipment.

Surface Grinding

For the grinding, satin finishing, deburring and polishing of a great variety of parts; using a through feed finishing process with multiple grinding/polishing operations.

Centerless Grinding/Polishing

“Centerless” type belt grinding and polishing machine with universal heads for finishing tubes and round bars with diameters from 6 to 150mm.

Flat Polishing

Polishing machine for sheet metal and flat parts. Table of 1250×3000 mm with alternative movement and polishing head with oscillation and automatic installation of polishing compound.

CNC HD

5 interpolated axes CNC machine with 1 double working head for polishing or satin finishing of aluminum car wheels.

Rotary Transfer

High production capacity installation composed of 2 rotary CNC transfer machines for the internal and external polishing of forged aluminum truck wheels up to 26″.

Robotic Cell

Robot cell equipped with 6 abrasive belt back stands, 1 double polishing unit and automatic tool changer magazine for up to 5 references, for finishing parts of the aeronautical sector.

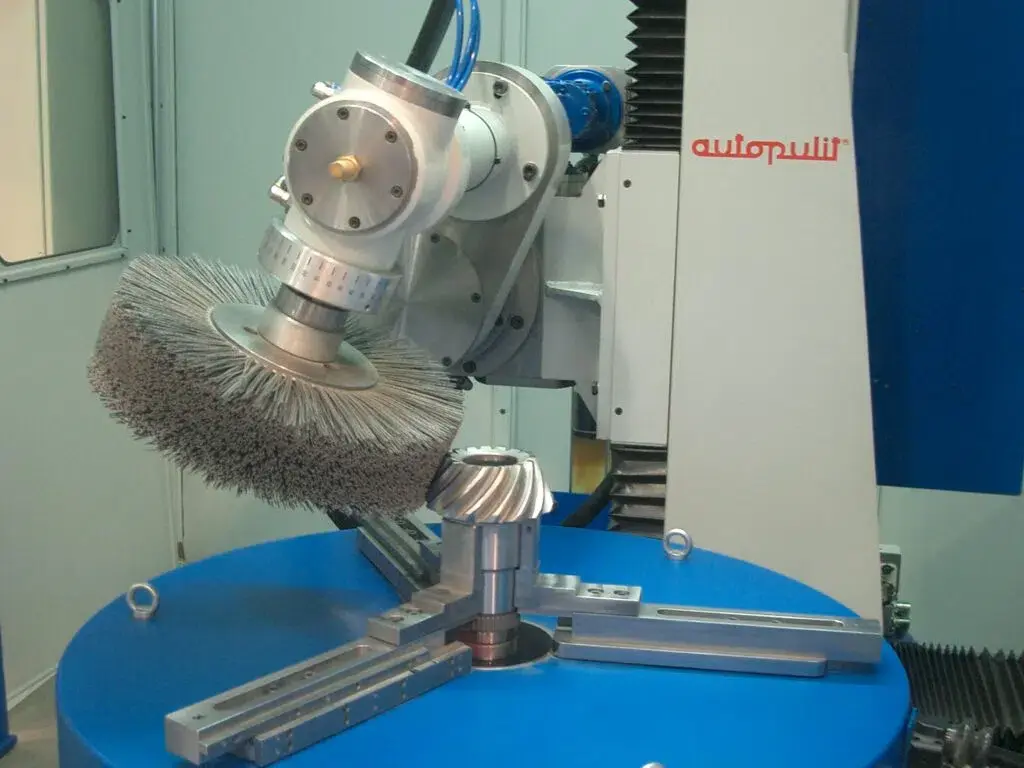

CNC Deburring

CNC machine with 5 interpolated axes for deburring and rounding the edges of spur, helical and hypoid gears for the aeronautical sector.